Products

We Provide Six Types Of Product Applications.

Sheet

Spartech thermoplastic sheets are typically extruded or cast into a thicker, flat form and can be produced in a variety of colors, sizes, transparency, and thickness. Sheet can be coextruded with multiple materials to enhance durability and physical properties.

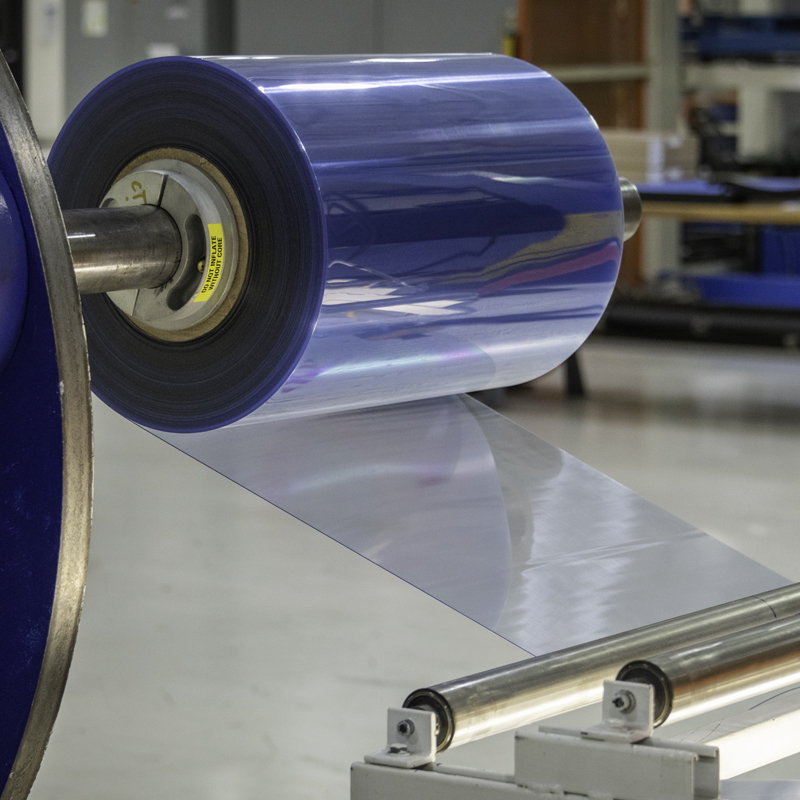

Rollstock

Spartech rollstock solutions are extruded or coextruded to customer specifications and requirements for material performance. Typical applications including calendering, lamination with decorative films, or protective films, slitting with width specs, and winding onto large or small rolls to meet production and shipping specs.

Film

Spartech films are typically extruded and printed with patterns — and offered in varying colors and transparencies, as well as differing physical properties such as scratch resistance, weatherability, and UV resistance. Spartech's vertical integration of manufacturing processes allows efficient production of film, printing, and laminating onto sheet.

Rigid Packaging

Spartech packaging film is extruded in either a single or multi-layer form. Depending on the number of layers and type of material, packaging film can provide low, medium, and high barrier capabilities. Film is sold in the form of rollstock or as preformed containers.

Rods and Tubes

Spartech rods and tubes are cast into various diameters, hollowness, transparency, and colors. They offer high optical clarity, close tolerances, and superior machinability relative to extruded variants and can be machined, polished, cut, drilled, or chamfered to meet specifications.

More resources

More resources

Looking for a specific product, solution, or help with product development, prototyping, and testing? Spartech has the team, skills, resources, and production facilities to meet your needs. Use these links to search our products, discover our range of specialized solutions, and learn more about our 90,000 square foot St. Louis Innovation Center.